The Cost of Recruitment

Excerpt from; The Driver Retention Masterclass – Section 11

I am going to take a close look at all of the costs associated with bringing on a new driver, and attempt to estimate the total price every time we do this. Other areas will also see cost reductions, but this is one of the most obvious.

Efficient cost management means not spending money that does not need to be spent. In hiring drivers, it is necessary to spend money to place ads, hire recruitment services, screen candidates, and then train and orient the latest drivers. But if the drivers do not stay long once hired, this money must all be spent again to find a replacement. An efficient approach would spend the recruitment, hiring, and orientation money a lot less often. Spending that money to repeat it all over again in less than a year for each driver is not an efficient use of limited, revenue funds. An efficient approach to managing these expenditures would focus on building an effective, responsive infrastructure to ensure that drivers, once hired, chose to stay longer with the company. Efficient cost management means reducing driver turnover.

Let’s consider some of the basic dollar numbers. Depending on the marketplace, the cost of recruiting a driver and helping him or her to become productive can range from $6,000 to $12,000. For some markets, it could be a lot more. For the sake of this discussion, let’s be conservative and say that it costs $9,000 to hire and get the driver productive; so, every time we hire a driver, it is going to cost us $9,000. You can see where this is heading. If we have 100 drivers and an 80% driver turnover rate, we are hiring 80 new drivers each year. With this rate and these costs, we will be spending $720,000 per year to hire drivers – every year.

If our company has an operating ratio of 95% (gross profit margin of 5%), we will need to generate $14.4 million dollars per year to service that annual expense of $720,000. And remember what we mentioned in an earlier section – a high turnover company can never operate efficiently; therefore, it is much harder to get and keep customers to provide that revenue. It is a vicious circle.

If we could reduce our turnover by half each year, we would reduce our onboarding cost by $360,000 per year. This would correspondingly reduce the revenue needed to support this expense to $7.2 million. Bearing in mind the company’s improved efficiency with a lower driver turnover rate, we might even be operating at better margins and need even less cost-covering revenue. It just keeps getting better.

But be sure to keep the focus on recruiting and hiring quality drivers. The objective is NOT to reduce the cost of hiring an individual driver. The aim is to minimize the OVERALL cost of hiring all of your drivers. It is acceptable to spend more per hire if the selection and retention is improved.

With these kinds of numbers, it is obvious that reducing driver turnover has the potential for substantial cost savings and improved profits. In our example, going from an 80% turnover to 40% saves $360,000 per year. These cost reductions drop straight to the bottom line as increased profits or can be used as new funds for business growth investment. Improving driver turnover has a significant, positive impact on business financial health.

With these numbers, all of a sudden reducing driver turnover becomes an obvious business objective.

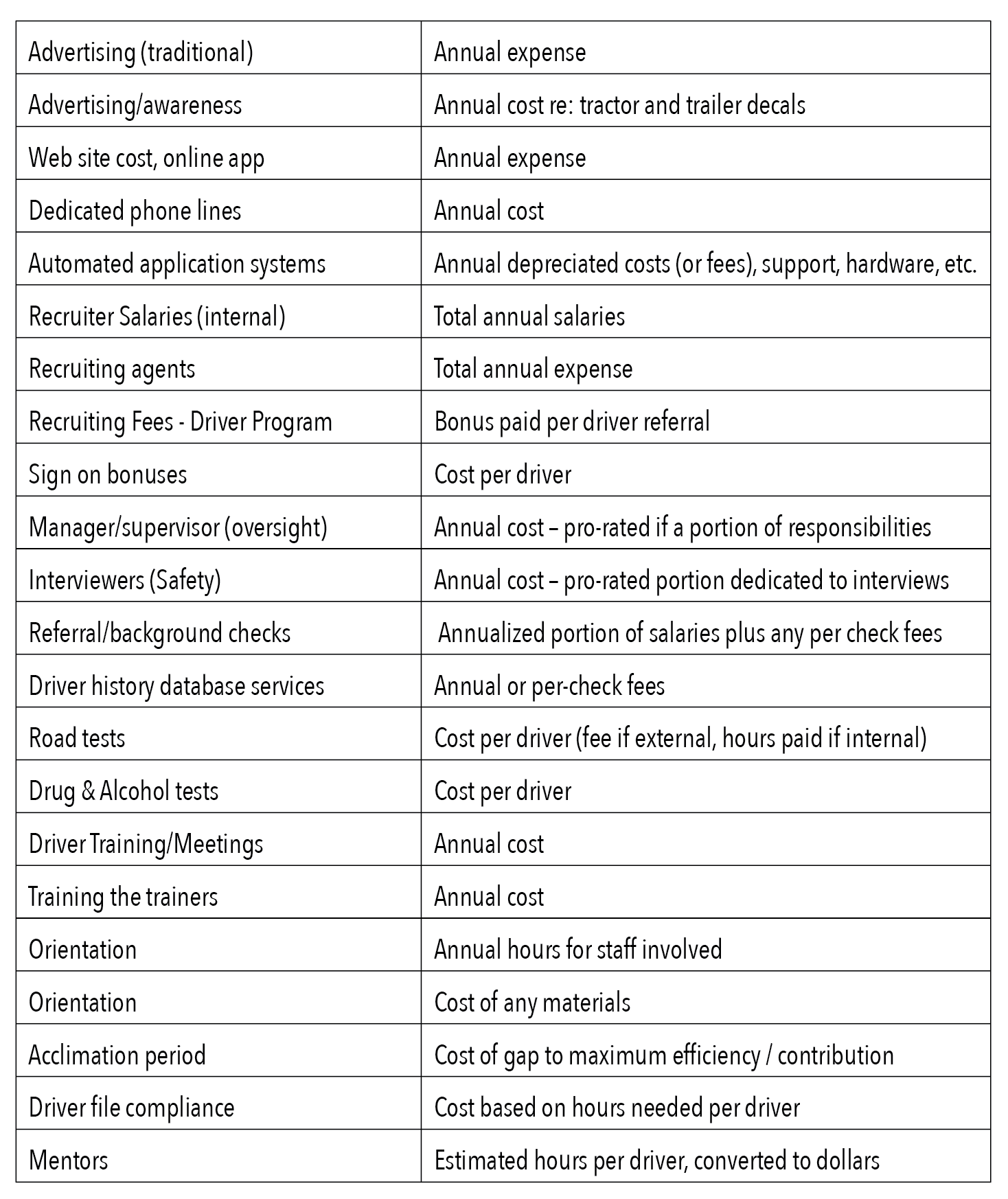

Earlier in this article, we suggested an average cost of $9,000.00 to find and bring a new driver up to speed. Your cost will be different, and you need to estimate your own costs. Start by making a list of the “costs” that apply to your situation. Here are some of the typical cost elements for you to consider when estimating your own cost of hiring:

NOTE: For costs listed as “annual,” the total must be divided by the number of “new” drivers per year to obtain what the “per driver” portion is:

This list is a sample to help get you started. You may have others that apply to your recruitment processes and environment. For instance, your industry or region might require some very specific skills that go well above the typical driver training and orientation sessions needed to onboard an experienced driver.

We also know that lower turnover usually means a safer carrier. Which in turn means lower insurance expenses, fewer accident claims, less wear and tear on equipment with fewer drivers rotating through and a higher residual value of rolling assets. Lower turnover means better turnaround of receivables by a better understanding of paperwork flow with seasoned drivers. Fewer service failures with less turnover means a stronger relationship with shippers and receivers.

Companies with lower turnover are more profitable companies. For you doubters, ask the heads of Operations, Safety, Administration, Maintenance and Operations what the cost savings might be if they were in an environment of 50% less turnover than they work with now, and then add these expenses into the cost of turnover. These numbers will likely far overshadow the $360,000 saved by 40% turnover compared to 80%.

Safe trucking,

Ray J. Haight

Co-founder

tcaingauge.com

Areas of Focus: Operations, Recruiting & Retention, Human Resources With a career spanning four decades, Ray has been involved in all facets of the North American Trucking Industry.